description flotation process iron ore

Types of Iron Ore: Hematite vs. Magnetite | INN

The deposit was discovered in 1844, and ore was first mined there in 1848. Magnetite ore and hematite ore are among the four types of iron ore deposits found in this area. In Minnesota, this type of iron ore is mined mainly in the Mesabi Range, one of the four ranges that make up the Iron Range of Minnesota.

Iron Ore Reverse Flotation Process

Froth Flotation of Iron Ores sapub. With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market.

From Ore to Finished Product

From its original home buried underground in a mine to its use in a finished product such as wire or pipe, copper passes through a number of stages. When it is recycled it .

Innovative Technique to generate saleable Iron Ore Fines ...

Kaoline, quartz are the main gaunge minerals in the ore. These coarser hematite and limonite ores are recovered by using crushing, log washing, drum scrubber, vibrating screens, classifiers and 3stages of hydro cyclones process. With the above process, particles above 45 microns are recovered.

CATIONIC FLOTATION OF SILICA AND APATITE FROM OXIDIZED ...

Mar 07, 2019· A process to beneficiate oxidized iron ore comprising: adding a causticized starch to the oxidized iron ore; adding at least one amine to the oxidized iron ore; adding at least one polyphosphate activator; and adding at least one salt; wherein the pH of the process is between approximately 6 and 9 inclusive; and wherein no desliming step is performed.

Iron Ore Processing for the Blast Furnace

The following describes operations at the National Steel Pellet Company, an iron ore mining and. processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from lowgrade iron ore requires a long process of mining, crushing, separating, concentrating, mixing, pelletizing, and. shipping.

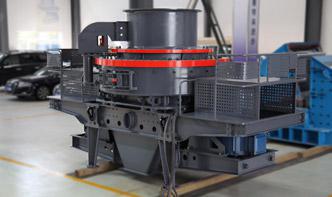

Reliable equipment for iron ore mines

We provide you with a full flowsheet of equipment that has made us the global leader in highefficiency process systems for iron ore and mineral beneficiation. Our site services teams provide the maintenance support and the spare parts to ensure the equipment continues to operate at optimum efficiency with minimum downtime.

Mining | Nouryon – HighPerformance Mineral Processing

Flotation of Iron Ore Our sustainable flotation collectors are optimal for removal of silicates and phosphoruscontaining minerals.

iron ore processing plant process description

The formation of raw iron ore pellets, also known as pelletizing, has the objective of producing pellets in an appropriate band of sizes and with mechanical properties high usefulness during the stresses of transference, transport, and use. Both mechanical force and thermal processes are used to produce the correct pellet properties. Get Price

Solution Yantai Jinpeng Mining equipment, ore dressing ...

Iron > Molybdenum > Nonmetal processing. Phosphorus > Barite > Kfeldspar > Graphite > Quartz sand > ... Fluorite flotation process. PbZn ore dressing process. Magnetite Separation Production Line. Gold flotation process. Acquaintance with us. Products >

Tastes of Chennai small iron ore crusher for sale in ...

small iron ore crusher for sale in malaysia, flotation cell 10 t for sale certified,10tph alluvial gold plant equipment All Categories Grinding Flotation Screening Crushing Classifying Separating Process Equipment Gold Extraction Equipment Thickening Dewatering Equipment Auxiliary Equipment

What Is the Difference Between Iron and Steel? |

The difference between iron and steel is that iron is an element, and steel is an alloy of iron, small amounts of carbon and another material, usually another element like chromium. Iron is alloyed with other elements to make it stronger and more useful and to keep it from rusting.

Energy and Environmental Profile of the Mining Industry 4

Iron ore occurs naturally in a variety of forms, from sandlike iron fines to solid rock masses. Crude ore, or ore mined in the natural state, seldom occurs in a pure state and requires some form of beneficiation.

Ore Flotation Oxide

flotation in mining copper and gold oxide ore. Flotation in mining copper and gold oxide ore. Flotation of mixed copper oxide and sulphide minerals . Flotation of mixed copper oxide and sulphide minerals with.

froth flotation of iron ore ppt– Rock Crusher MillRock ...

froth flotation of iron ore ppt is a leading global manufacturer of crushing and milling equipment (froth flotation of iron ore ppt), also supply individual (froth flotation of iron ore ppt...) crushers and mills as well as spare parts of them.

Project brief Freelance Modernization of mining ore plant ...

finishing process the entire magnetic flotation technology department manages the process using a complete distributed automation system. After many years of successful operation using Freelance, it was decided to expand and upgrade to version in March 2012. Technologically Advanced Mining Operations in Ukraine Ingulets Iron Ore Enrichment Works (Ingulets GOK) is one of the largest iron ore .

mineral flotation cell description

Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic. Contact US Froth Flotation Department of Chemical Engineering. Figure 5: Simplified schematic of a conventional flotation cell. . The properties of raw mineral mixtures suspended in plain water are rarely suitable for froth. Contact US Flotation: Advantage Circular Cells Mining Technology. Jan 13, 2012 .

Iron Ore 1st Edition

Description. Iron Ore: Mineralogy, Processing and Environmental Issues summarizes recent, key research on the characterization of iron ores, including important topics such as beneficiation (separation and refining), agglomeration (, production of pellets or powders), blast furnace technology for smelting, and environmental issues relating...

Development of NML's Taconite Project concentrator ...

Development of NML's Taconite Project concentrator flowsheet to optimize operating cost and achieve high quality products. Presented by: Rock Gagnon, ing.

Mining Flotation Chemicals Market Global Industry ...

Ore Type Analysis. In terms of type of ores, global mining flotation chemicals is segmented into sulphide ores and nonsulphide ores, which bespeak consumption of mining flotation chemicals for these two types of ore. In 2014, sulphide ores accounted for around 68% of .

ore flotation contents

flotation iron ore and sulphur in the iron ore Grinding ... In iron ore mining, miner usually choose a complete iron ore crushing plant for metallurgy. Iron ore beneficiation process Almost all of the iron ore that is mined is used for making steel.

Latest Posts

- بيع كسارات الحجر الصغيرة

- صناعة تكسير الصخور في نيكاراغوا

- إعادة تدوير سحق الخرسانة في اليمن

- معدات سخان مجفف دوار

- خطوة رئيسية في معالجة خام الحديد

- مصنع طحن الدولوميت

- التصميم المطرقة مطحنة لقوات الدفاع الشعبي الفحم

- role de la geologie dans la carriere

- forces de minerai de fer de conduite

- marteau catalogue de l usine pour l alimentation animale

- différents concasseurs à mâchoires

- 60 mil prix etang de ligne

- car shredder line manufacturing in iran

- kursus tentang onsetting tambang

- concasseurs armstrong hollande

- concrete grinding companies in zimbabwe

- Manufacturers Suppliers 31

- caracteristicas de los recursos industriales

- mining machine suppliers in australia

- manganese crusher service

- bridgeport millingmachine

- stone crusher project report china

- سنگ شکن های شن برای فروش در brampton

- تامین کننده آسیاب چکش در زامبیا

- آسیاب های توپ فرآوری سنگ معدن مس را پردازش می کنند

- دستگاه سنگ زنی سنگ مرمر برای فروش

- استفاده از سنگ شکن های تلفن همراه قیمت آفریقای جنوبی

- تجهیزات خرد کردن ذغال سنگ هند

- trituradora para moler vidrio

- تجهیزات سنگ شکن خزش