smelting reduction of lean iron ore

purification of copper by electrolysis metal .

How do we purify impure copper obtained from smelting copper ... change from the copper ore reduction ore using ; Iron ... Purification of Copper by Electrolysis ...

Smelting reduction | metallurgy |

In iron processing: Smelting reduction .the shaft before being discharged. The scarcity of coking coals for blastfurnace use and the high cost of coke ovens are two reasons for the emergence of this other alternative ironmaking process. Smelting reduction employs two units: in the first, iron ore is heated and reduced by gases. Read More

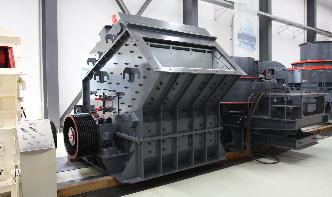

ultra lean ore crusher

ultra lean ore crusher canola crushing plant in beasejour, manitoba. smelting reduction of lean iron ore ... More detailed ULTRA Grind+ Wet ...

ultra lean ore crusher

lean iron ore upgrading Method for upgrading iron ore utilizing ... system for ultralean ... smelting reduction of lean iron ore crusher machine. iron ore smelting process plant ...

extraction 0f vanadium titanium from iron ore

Smelting reduction of titaniumbearing iron ore in blast furnaces has ... Lean iron ore, complex iron ore and refractory iron ore account for above 90% ...

BBC GCSE Bitesize: Making iron

Making iron In the blast furnace. ... Reactions in which oxygen is removed are called reduction reactions. ... iron ore (haematite)

Ironmaking 101 – From Ore to Iron with .

In the smelting reduction process, pelletized iron oxide ore or fine ore powders are prereduced in a fluidized bed or reduction shaft. The reduced iron along with coal and lime is fed to a gasifiermelter, which completes the reduction process and produces pig iron or hot metal of the same quality as a blast furnace.

Smelt reduction for iron and steel sector | .

However, coals suitable for smelt reduction are available in quantity, and the coal is available "on the doorstep" of the iron ore reserves. The smelting reduction process can use iron ores high in alkali content, as found in South Africa (Wintrell, 1992).

EVALUATION OF THE CAPABILITIES OF DIRECT AND SMELTING ...

smelting reduction processes to enhance the energy efficiency and to reduce the co 2 emission of the steel production in europe ... iron ore source reduction

Hydrogen Plasma Smelting Reduction of Iron Oxide .

Hydrogen Plasma Smelting Reduction of Iron Oxide and its Process ... selected for smelting reduction investigations in ... Reduction of Iron ore by a mixture ...

How to calculate metallization degree in iron .

Get expert answers to your questions in Smelting, Iron, ... How to calculate metallization degree in iron ... ore beneficiation, agglomeration, reduction and ...

Electric furnace reduction of iron ore Lehigh Preserve

Electric furnace reduction of iron ore ... the smelting zone is increased by drying the blast, and thus removing the strong cooling influence which the decomposition

Required Manufacturers Iron Smelting Plants

required manufacturers iron smelting plants,required suppliers iron ... smelting reduction of lean iron ore Crusher Center. iron ore smelting process ...

Iron Ore | HowStuffWorks

Smelting involves heating up ore until the metal becomes spongy and the chemical compounds in the ore begin to break down. Most important, it releases oxygen from the iron ore, which makes up a high percentage of common iron ores. The most primitive facility used to smelt iron is a bloomery.

Corex Process | Industrial Efficiency Technology .

Corex is a smelting reduction process combining a melter gasifier with a reduction shaft. The process takes lump iron ore or pellets, noncoking coal, and oxygen as main inputs. Similar to the blast furnace process, the reduction gas moves in counter flow to the descending burden in the reduction shaft.

Smelting Reduction of Iron OreCoal .

Smelting reduction of iron orecoal composite pellets has been carried out in an induction furnace. The pellets, tied with tungsten wire, were immersed into the ...

smelting reduction of lean iron ore .

The relationship between coal consumption and iron ore reduction in the ... the path from "iron ore to .... smelting reduction processes ... These lean gases can be. Read more; latest development of the slrn direct reduction process. smelting reduction of lean iron ore – Grinding Mill China.

ARCHAEOLOGY DATASHEET 301 Iron: bloomery smelting .

Iron: bloomery smelting and associated processes ... bloomery smelting and ... Two important reactions occur during smelting; the reduction of iron oxide to ...

China coalbased tunnel kiln method of .

Annual import of reduction iron in China was around 3,000,000,while the annual output of reduction iron(sponge iron) was only 600, is a country with rich lowiron ore resources,lowleandead ore occupies over 97% of iron ore resources,however,China has to import annually 600,000,000 tons iron ore from foreign countries,the rich lowlean .

Kinetics for Reduction of Iron Ore Based on the .

A series of smelting reduction experiments has been carried out with highphosphorus iron ore of the different bases and heating rates by thermogravimetric analyzer. The derivative thermo gravimetric (DTG) data have been obtained from the experiments.

Iron | Iron Ore | Smelting Scribd

ITmk3. Smelting is melting involving chemical reduction reactions. the life of high grade lumpy ore as on 1. The various processes of SR technique are COREX. Most smelting reduction processes also avoid the agglomeration of iron ore. Value addition to the iron ore fines through various activities such as beneficiation.

Introduction to slag analysis: How iron is made .

28/11/2011· If the above pathway of reduction is correct, the ore is reduced ... ever find iron at a smelting ... Introduction to slag analysis: How iron is ...

A study on reduction kinetics of titaniferous .

A study on reduction kinetics of titaniferous magnetite ore using ... titaniferous magnetite ore (TMO) and lean grade coal briquettes ... the reduction of iron ...

3rd International Conference on Process Development .

3rd International Conference on Process Development in Iron and ... Smelting Reduction with CCS ... are mostly generated during the reduction of iron ore

Latest Posts

- كسارة الفك pisau pisau

- 4 الأسطوانة ريموند طاحونة مع أفضل الأسعار

- الحجر المحمول محطم جمهورية التشيك

- العالم أكبر الشركات المصنعة كسارة الحجر

- مصنع الأسمنت الدائرة المفتوحة والمغلقة

- استخدمت الصين أسعار الكسارات مخروط

- تستخدم كاملة كسارة الحجر النباتية

- fraisage des pieces de machines de concassage

- charbon fabricant de installation de pulverisation uae

- calculs de poudre de broyage fin

- recherche concasseur de pierre mobile occasion

- ampli de broyage dans les industries de briques

- fabrication concasseur à jabalpur

- gomme machine concasseur bruit

- faire la pierre de la machine et de sable

- Mobile Crushers 2014

- grinding machine engines

- second hand conveyor belts in perth australia

- sand manufacturing method australia

- dan bagian stone crusher

- mtm trapezium mill grinder

- gold mining zimbabwe areas

- کارخانه چین فروش آسیاب چوبی کوچک چند منظوره کوچک

- قیمت سنگ گچ خرد شده قیمت بازار هند در هند

- سنگ شکن مخروط میکا

- استخدام سنگ شکن صفحه نمایش

- اجاره سنگ شکن میشیگان

- خرد کردن گیاه گورو

- لیست گیاهان آزمایش سنگ شکن سنگ

- قیمت تجهیزات معدنی در مقیاس کوچک در آفریقای جنوبی